Ok, my flux cleaner arrived and I cleaned the board. The cleaner really makes a difference in being able to see everything once again.

I can now tell that I didn't damage the board as horribly as I once thought.

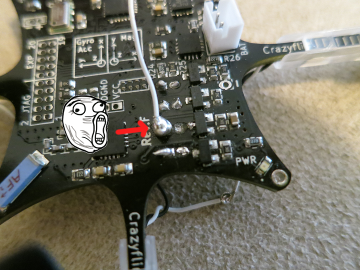

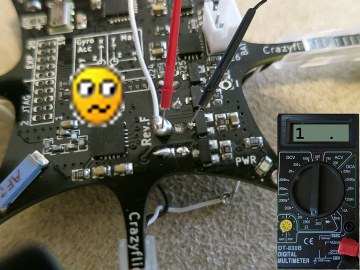

My problem with M3 not spinning still remains, but I have solid multimeter readings to report to try to debug the issue and, hopefully, I can use a patch wire to correct the issue (which I have already attached). First, here is a photo of my board. You will notice that I obliterated the pads for M3 when I was originally using a soldering wick and trying to remove the solder from the hole in the pad. This damage was done before I figured out that I could easier pop the new motor wire through the reverse side, and is probably the source of my problem.

- original_board.png (182.95 KiB) Viewed 12186 times

When using a multimeter I miraculously find that the connections for the M3 wires are still working, except for one: square pad to transistor. I am hoping someone more knowledgeable could instruct me as to where I could connect a patch wire? Or otherwise help me figure out why square pad to transistor connection is not working? M3 Square pad to +BATT works and M3 Square pad to circle works, so some parts of the M3 square pad are ok ok. Here are my readings, with photos..

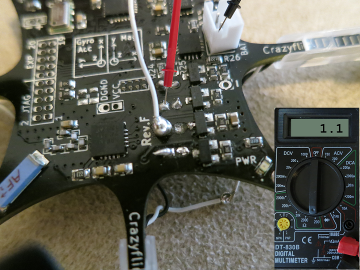

Square pad to BATT+ (M3 pad also successfully registers this value):

- measurement_square_battplus.png (181.92 KiB) Viewed 12186 times

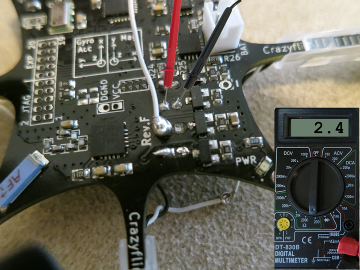

Square pad to circle pad (M3 pad also successfully registers this value):

- measurement_square_circle.png (204.66 KiB) Viewed 12186 times

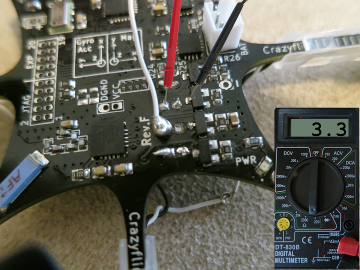

Square pad to transistor:

- measurement_square_transistor.png (204.78 KiB) Viewed 12186 times

M3 square pad to transistor (problem identified):

- measurement_m3_no_connection.png (181.67 KiB) Viewed 12186 times

Thanks for any help you can provide!